Diecasting has established itself as a critical manufacturing process in Malaysia, driving growth across various industries such as automotive, electronics, and consumer goods. By using molten metal injected into steel molds under high pressure, diecasting creates components that are not only precise but also highly durable. Malaysia’s position as a strategic manufacturing hub in Southeast Asia, combined with its skilled workforce and advanced infrastructure, has made it a preferred destination for diecasting services. The country’s manufacturers are recognized for their commitment to quality, innovation, and sustainability, making Malaysia a vital player in the global supply chain. As industries continue to demand lightweight and complex components, Malaysia’s diecasting sector is poised for sustained growth.

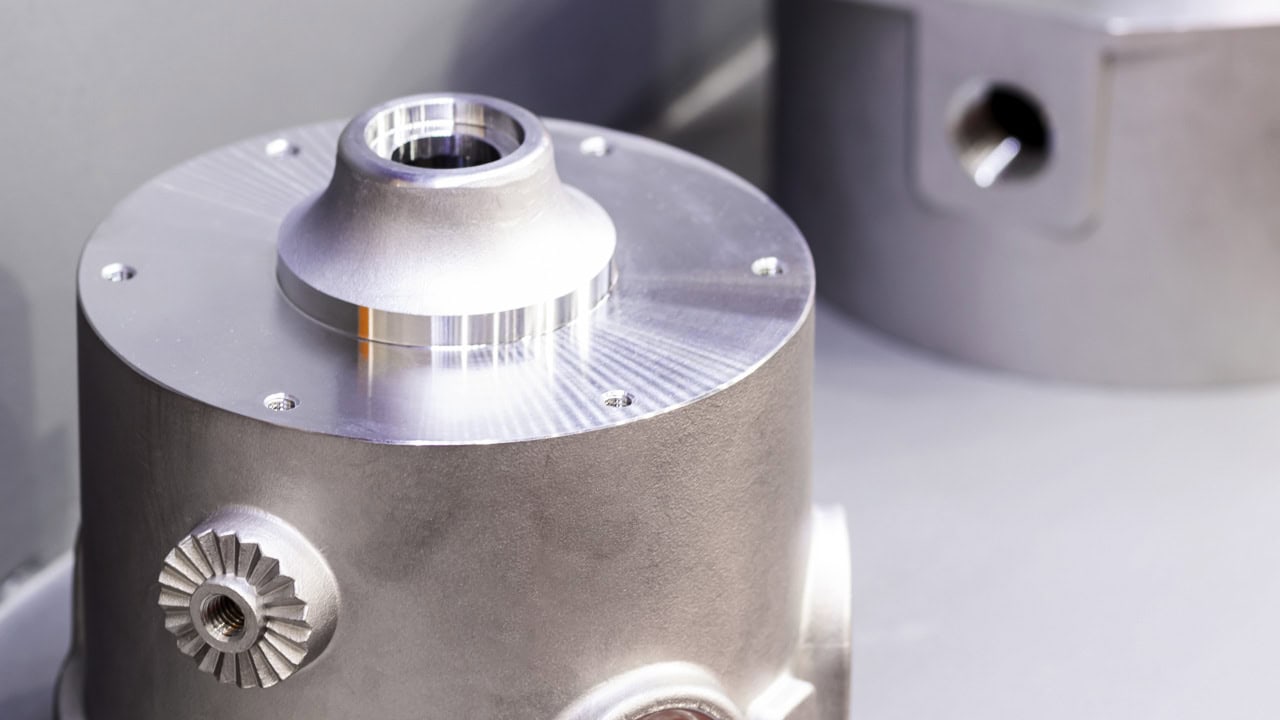

One of the primary reasons Malaysia excels in diecasting is its ability to produce high-quality components tailored to meet the demands of various sectors. Diecasting offers a level of precision that is unmatched by many other manufacturing techniques, allowing Malaysian manufacturers to create intricate designs and tight tolerances. Aluminum, zinc, and magnesium are the most commonly used materials, valued for their lightweight properties and structural integrity. In the automotive sector, for example, diecast components such as engine blocks, gearboxes, and brackets are essential for reducing vehicle weight and improving fuel efficiency. Malaysian manufacturers have positioned themselves as leaders in this area, supplying diecast parts to major international automakers and Tier 1 suppliers.

The electronics industry in Malaysia also benefits significantly from the local diecasting sector. The ability to produce thin-walled, complex components is critical for electronic devices where space and weight are major considerations. Heat sinks, enclosures, and connectors made through diecasting play a pivotal role in maintaining the performance and reliability of consumer electronics and telecommunications equipment. Malaysia’s expertise in precision engineering ensures that these components meet stringent quality standards required by global technology brands. As demand for electronic devices continues to rise, Malaysian diecasters are poised to play a crucial role in supporting the rapid growth of this sector.

Sustainability is another defining feature of die casting company Malaysia, as the industry adopts eco-friendly practices to reduce its environmental footprint. Diecasting is inherently efficient, with minimal material waste due to the recyclability of metals such as aluminum and zinc. Malaysian manufacturers are taking this a step further by implementing energy-efficient technologies, such as advanced melting furnaces and automated production lines, to reduce energy consumption. Closed-loop recycling systems are also being adopted, ensuring that scrap material is reprocessed and reused within the production cycle. These efforts not only align with global sustainability goals but also enhance Malaysia’s competitiveness in the international market, where eco-conscious practices are increasingly prioritized.

The growth of diecasting in Malaysia has been supported by government initiatives that encourage innovation and skill development. Programs such as tax incentives for technology adoption and grants for research and development have enabled manufacturers to invest in advanced equipment and automation. At the same time, collaborations with technical institutions and universities have helped cultivate a skilled workforce proficient in operating high-tech machinery and maintaining production quality. This combination of technological advancement and human expertise has allowed Malaysian diecasters to remain competitive in a rapidly evolving industry, attracting clients from around the globe.

Diecasting in Malaysia is a testament to the country’s strength in precision manufacturing, delivering high-quality components that meet the needs of diverse industries. Its ability to produce lightweight, complex, and durable parts has made it a cornerstone of the automotive and electronics sectors. By embracing sustainability and leveraging innovation, Malaysia’s diecasting industry continues to solidify its reputation as a reliable and forward-thinking player in the global supply chain. With rising demand for high-performance components and eco-friendly solutions, Malaysia’s diecasting sector is set to play an even greater role in shaping the future of manufacturing.