Diecasting spreading is a vital procedure in modern manufacturing, commonly made use of to create high-grade metallic components along with accuracy and also sturdiness. In Malaysia, the Diecasting market has grown substantially, steered through developments in modern technology, proficient effort, as well as a solid manufacturing sector. The nation has actually become a center for Diecasting procedures, supplying components to numerous fields such as automobile, aerospace, electronics, and also customer items. With the boosting demand for lightweight as well as high-strength steel components, Malaysian Diecasting companies have constantly enhanced their capacities, integrating impressive creation techniques to fulfill global requirements. The calculated area of Malaysia, coupled along with its own well-developed framework and business-friendly policies, has actually created it a recommended location for Diecasting production. As fields remain to evolve, Malaysia stays at the forefront of preciseness Diecasting spreading, giving dependable remedies for both regional and worldwide markets.

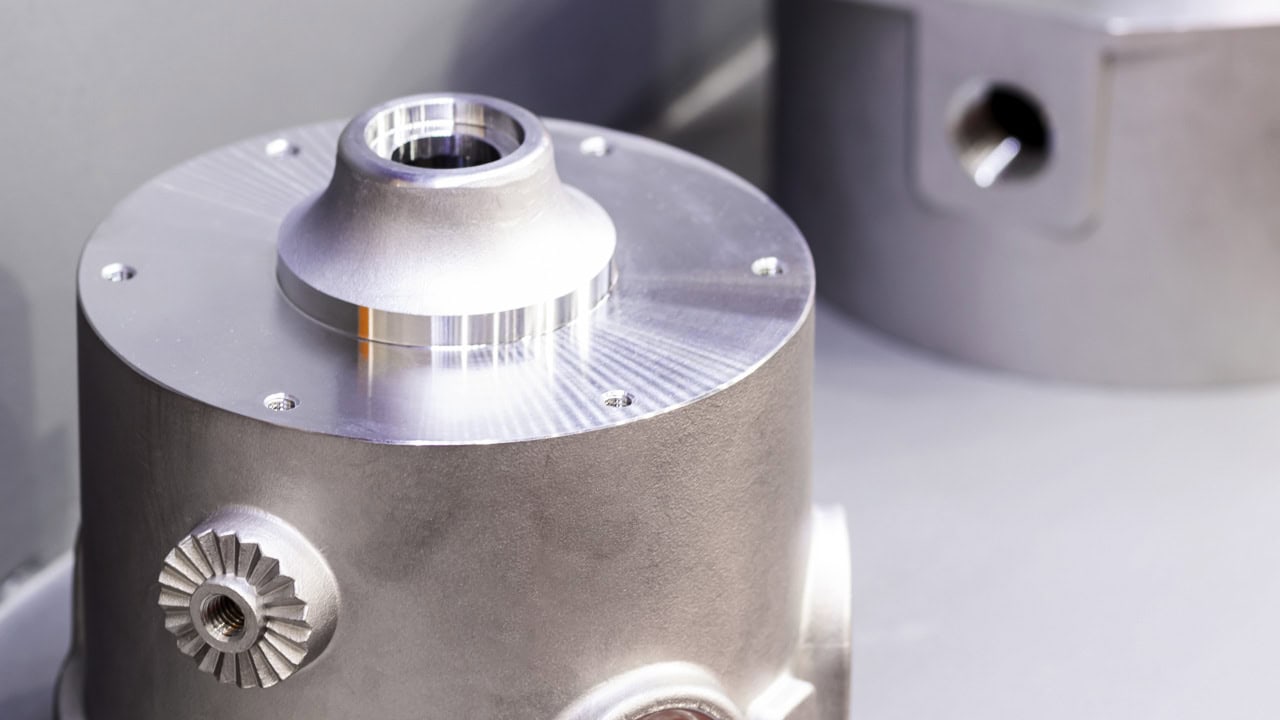

The Diecasting method in Malaysia largely involves two principal kinds: high-pressure Diecasting and low-pressure Diecasting. Stressful Diecasting is the best generally used strategy, where liquified metal is injected into a mold tooth cavity under higher tension, enabling for the quick production of facility and precise parts. This strategy is actually largely utilized in the automobile and also electronics industries, where higher precision as well as strength are actually needed. Alternatively, low-pressure Diecasting is made use of for creating bigger components along with premium technical homes, making it best for business including aerospace as well as commercial equipment. Many Diecasting directing providers in Malaysia additionally give additional procedures such as CNC machining, surface procedure, as well as assembly to make certain that finished products meet the specific specs of their clients. The continuous fostering of innovative Diecasting technologies has actually enriched productivity as well as high quality, helping make Malaysia a forerunner in this particular area.

Some of the crucial benefits of the Diecasting field in Malaysia is its own capability to create cost-effective and also high quality metallic elements. The performance of the Diecasting procedure enables assembly-line production with minimal product refuse, creating it a popular option for manufacturers finding money-saving solutions. Also, die-cast parts possess great perspective accuracy, removing the need for substantial post-processing, which better decreases development prices. Malaysian producers have actually also invested in automated Diecasting systems, improving development rate and also uniformity while maintaining strict high quality command solutions. The capacity to produce light-weight but durable parts has added to the business’s growth, particularly in industries where weight decline participates in an essential job, such as motor vehicle as well as aerospace. By continuously maximizing development techniques, Malaysia has placed on its own as a competitive gamer in the global Diecasting market.

The vehicle sector is among the biggest customers of die-cast elements in Malaysia, relying on these components for motor housings, transmission instances, building braces, and also various other essential requests. As the vehicle field changes towards power lorries (EVs), the need for light in weight aluminum die-cast parts has enhanced dramatically. Malaysian Diecasting business have actually conformed to this fad through creating concentrated blends and processes to fulfill the stringent needs of EV suppliers. Also, lots of regional organizations have created partnerships with global automobile companies, providing precision-engineered die-cast parts that boost vehicle performance as well as gas efficiency. With the increase of environment-friendly modern technology and sustainable production, Malaysia’s Diecasting industry remains to innovate, sustaining the change to additional green transit remedies. For more information please Check This Out

Past the automobile sector, Diecasting in Malaysia also participates in a critical function in the electronics and telecommunications fields. Several digital units as well as elements require die-cast casings and warmth sinks to ensure dependable warm waste and also protection from outside factors. With the fast development of customer electronics and 5G innovation, Malaysian makers have scaled up their die appointing capabilities to satisfy the improving requirement for high-precision components. The capacity to generate elaborate and also light-weight components along with first-rate thermic energy has produced Malaysian Diecasting providers crucial distributors for international technology agencies. Furthermore, the authorities’s campaigns to ensure innovative manufacturing as well as digitalization possess more built up Malaysia’s location as a popular place for Diecasting companies in the electronic devices market.

The future of Diecasting in Malaysia appears promising, with ongoing expenditures in study, development, and also computerization. As the requirement for high-performance metal parts grows, Malaysian manufacturers are concentrating on lasting techniques, such as reprocessing light weight aluminum composites and decreasing power consumption in the manufacturing process. The integration of Field 4.0 modern technologies, featuring fabricated intellect as well as records analytics, is actually additionally helping providers boost performance, reduce flaws, as well as improve item high quality. Along with a skilled workforce, strong commercial commercial infrastructure, and devotion to innovation, Malaysia continues to be a principal in the global Diecasting sector. As additional fields seek light in weight and sturdy metal solutions, the Malaysian Diecasting market is set to expand better, improving its own track record as an innovator in preciseness manufacturing.